Semiconductor supply news trends: what you need to know

Semiconductor supply news trends are significantly influenced by global events, technological advancements, and sustainability initiatives, making it essential for businesses to adapt their strategies to remain competitive in the evolving market.

Semiconductor supply news trends are becoming increasingly crucial for understanding the tech landscape. As new developments emerge, how will these trends affect your business decisions?

Current trends in semiconductor supply chains

Current trends in the semiconductor supply chains are evolving quickly. As industries grow and technology advances, understanding these trends is essential for businesses looking to stay competitive.

Global Supply Chain Challenges

Today’s semiconductor industry faces numerous challenges. Global events like pandemics and geopolitical tensions impact supply routes. These disruptions can lead to delays in production and shortages of critical components.

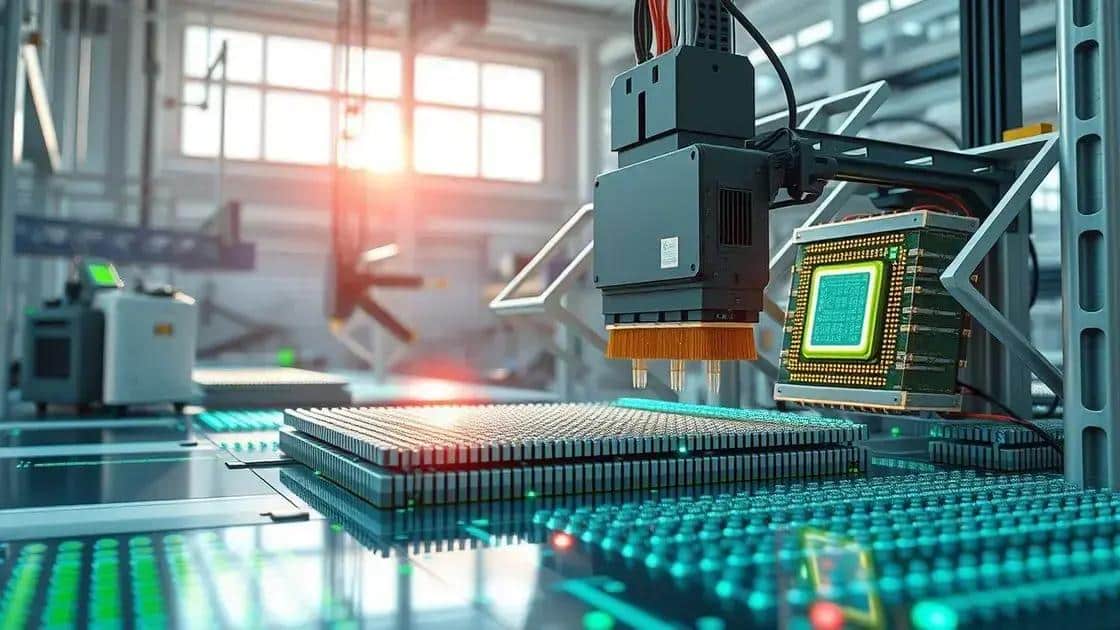

Innovation in Manufacturing Processes

Manufacturers are investing heavily in advanced technologies to improve production efficiency. Technologies like automation and AI are transforming how semiconductors are made. This innovation helps optimize output while maintaining quality.

- Improved efficiency through automation

- Use of AI for quality control

- Advanced materials in semiconductor fabrication

Furthermore, companies are exploring new materials which enhance performance and reduce costs. With these advancements, the industry is becoming more resilient to future disruptions. Businesses that adapt to these changes are likely to gain a competitive edge.

Shifts in Consumer Demand

The demand for semiconductors is shifting rapidly due to the increasing reliance on electronic devices. Smartphones, automotive technology, and IOT devices require innovative semiconductor solutions. Understanding this trend is crucial for manufacturers looking to meet market needs.

In addition, companies are exploring sustainable practices in their supply chains. These practices are designed to not only boost efficiency but also minimize environmental impact.

Impact of global events on semiconductor availability

The impact of global events on semiconductor availability is significant and far-reaching. As industries rely more on technology, understanding these impacts becomes crucial for effective planning.

COVID-19 Pandemic Effects

The COVID-19 pandemic has profoundly affected semiconductor production. Lockdowns hindered manufacturing and slowed shipments. Many companies faced disruptions, which led to a global chip shortage. This shortage impacted various sectors, including automotive and electronics.

Geopolitical Tensions

Geopolitical tensions also play a role in semiconductor availability. Trade disputes between countries can lead to tariffs and restrictions, complicating supply chains. In particular, restrictions on technology exports can limit access to critical components and technologies.

- Impact on supply chains

- Increased costs due to tariffs

- Shifts in sourcing strategies

Additionally, these tensions can cause companies to rethink their sourcing strategies, looking for more reliable partners. The uncertainty created by these events pushes businesses to adapt to remain competitive.

Natural Disasters and Climate Change

Natural disasters also disrupt semiconductor supply. Events like earthquakes and floods can close manufacturing plants and delay shipments. Furthermore, climate change poses long-term risks to infrastructure. Companies must consider these potential disruptions when planning.

Overall, understanding the impact of global events on semiconductor availability is vital for both manufacturers and consumers. As the market continues to evolve, staying informed will help businesses navigate challenges effectively.

Strategies for businesses to adapt to supply changes

In today’s fast-changing semiconductor market, businesses need effective strategies to adapt to supply changes. These strategies are essential for maintaining competitiveness and ensuring a smooth operation.

Diversification of Suppliers

One effective strategy is diversifying suppliers. Relying on multiple suppliers can minimize risks associated with shortages. By working with various partners, businesses can secure the necessary materials even when one source is disrupted.

- Identifying suppliers in different regions

- Building relationships with secondary suppliers

- Assessing supplier reliability

This approach not only mitigates risks but also encourages competition among suppliers, which can lead to better pricing.

Investing in Technology

Investing in supply chain technology is also crucial. Tools such as real-time tracking systems and predictive analytics can provide valuable insights. These tools help companies forecast demand more accurately and manage inventory efficiently.

Moreover, leveraging technology streamlines communication within the supply chain. Improved communication with suppliers can lead to faster response times and better collaboration.

Building Strong Relationships

Building strong relationships with suppliers can also enhance resilience. Regular communication ensures that both parties understand expectations and challenges. Engaging in open discussions about potential disruptions allows businesses to prepare for changes.

Additionally, collaborating with suppliers on joint planning can lead to better alignment of production schedules and inventory levels.

Developing Flexible Manufacturing Processes

Finally, adopting flexible manufacturing processes is essential. This flexibility allows businesses to adapt to fluctuations in supply and demand quickly. By implementing modular systems, companies can adjust production lines as needed.

Overall, combining these strategies positions businesses to navigate the uncertainties of the semiconductor supply chain effectively. Being proactive in adapting to changes can lead to long-term success.

Future predictions for semiconductor trends

Future predictions for semiconductor trends indicate an exciting and rapidly evolving landscape. As technology advances, the demand for semiconductors will only grow, influencing various industries.

Increased Demand for Advanced Technologies

As devices become smarter, the need for advanced semiconductors will rise. Technologies like 5G and AI will drive innovations in semiconductor design and manufacturing. Companies must invest in research and development to keep up with these trends.

Sustainability in Semiconductor Production

Another important trend is the shift toward sustainability. As environmental concerns grow, semiconductor manufacturers are seeking ways to reduce their carbon footprint. This includes using eco-friendly materials and improving energy efficiency during production.

- Implementing green manufacturing practices

- Investing in renewable energy sources

- Recycling materials to minimize waste

These practices not only benefit the environment but can also enhance a company’s reputation and marketability.

Geopolitical Influences on Supply Chains

Geopolitical dynamics will also shape the future of semiconductor supply chains. Ongoing trade tensions may lead to shifts in where semiconductors are produced and sourced. Companies will need to be agile, adapting their strategies to navigate these challenges effectively.

Moreover, collaboration among countries may play a role in mitigating risks. By partnering on research and development, nations can share knowledge and resources.

Technological Advancements in Manufacturing

Lastly, technological advancements in manufacturing processes are expected to revolutionize the industry. Innovations in production techniques, such as 3D printing and machine learning, will likely improve efficiency and reduce costs. Manufacturers embracing these trends will be well-positioned for success in the competitive market.

Overall, understanding these future predictions will be essential for businesses looking to thrive in the semiconductor sector.

In conclusion, the future of the semiconductor industry is set to be dynamic and filled with challenges and opportunities. Understanding the changing landscape is essential for businesses looking to thrive. By adopting strategies like diversifying suppliers, investing in technology, and focusing on sustainability, companies can better adapt to shifts in supply and demand. Staying informed about global events and technological advancements will position businesses for success in the evolving market.

\n\n\n

\n

\n

FAQ – Frequently Asked Questions about Semiconductor Supply Trends

What factors are driving changes in semiconductor supply chains?

Factors such as global events, demand for new technologies, and geopolitical tensions are significantly impacting semiconductor supply chains.

How can businesses prepare for semiconductor shortages?

Businesses can prepare by diversifying their suppliers, investing in technology, and developing flexible manufacturing processes to adapt to changes.

Why is sustainability important in semiconductor production?

Sustainability reduces environmental impact, enhances brand reputation, and can lead to cost savings through efficient practices.

What role does technology play in the future of semiconductors?

Technology is crucial for innovation in manufacturing processes, improving efficiency, and adapting to the growing demand for advanced semiconductor products.